Parts of household appliances are interconnected, forming a single mechanism for completing assigned tasks. When one or several parts fail or a violation of their normal operation occurs, the problem’s cause should be found and eliminated. To facilitate this process, manufacturers of automatic washing machines Samsung have developed a system of codes that appear on the display when a specific problem occurs. Consider what the error code 3E and its analogs mean, and how to resume the operation of the equipment.

The reason for the display of code 3E and its meaning

On the machine’s display, error code 3E appears most often when there is a malfunction or malfunction in the tachometer or Hall sensor, in case of engine failure or a malfunction in the control module. In newer models, the cause may be a problem with the vibration sensor.

Important! 3E has analogs in different models of washing machines. So, for Samsung cars manufactured before 2008, the symbols EA will appear on display, in later models, until 2013 – 8Е, 8Е1, 8С, 8С1. If the appliance is not equipped with a display, the error is manifested by two constantly flashing red temperature indicators 40 and 60 ° C and flashing indicators of the washing mode.

At what stages does the device generate an error:

- after loading the laundry and pressing the “Start” button (the drum makes several revolutions and stops);

- after draining the water when switching to rinse;

- during spin laundry when the drum cannot gain the desired speed.

Consider situations that can lead to the appearance of error code 3E:

- Too much loaded laundry. The manufacturer indicates the weight of dry items in kilograms, which can be washed in one session. Excess laundry in the drum, as well as its uneven distribution, can lead to insufficient engine power to spin the drum to the optimum speed and to balance problems.

- Foreign objects falling into the space between the tank and the drum can jam it, making rotation impossible, and an error will appear.

- A small malfunction or complete failure of the control module.

- Failure of tachometer or vibration sensors.

- Faulty motor drive. May occur due to stretching or delamination of the drive belt.

- Engine power has decreased due to brush wear or winding breakage.

Each of these problems can be solved either independently or using the wizard.

How to fix the error and return the machine to working condition

To the machine began to wash again, you need to determine the cause of the failure and eliminate it. For this, it will be necessary to perform several simple manipulations if the problem is insignificant. With a more severe breakdown, equipment repair and replacement of failed parts may be required. We will figure out what actions to take in a particular situation.

Overloading the laundry of the drum or blocking it with some object

This is one of the most common problems that can be easily fixed at home. It is enough to turn off the appliance, pull out excess items, and start washing again. If the loading door is locked, unplug the power cord and wait a few minutes. After some time, the door can be opened and pulled out.

When jamming between the drum and the tank wall of a foreign object, you will have to remove the front cover of the device and remove the jammed object through the hole for the heating element.

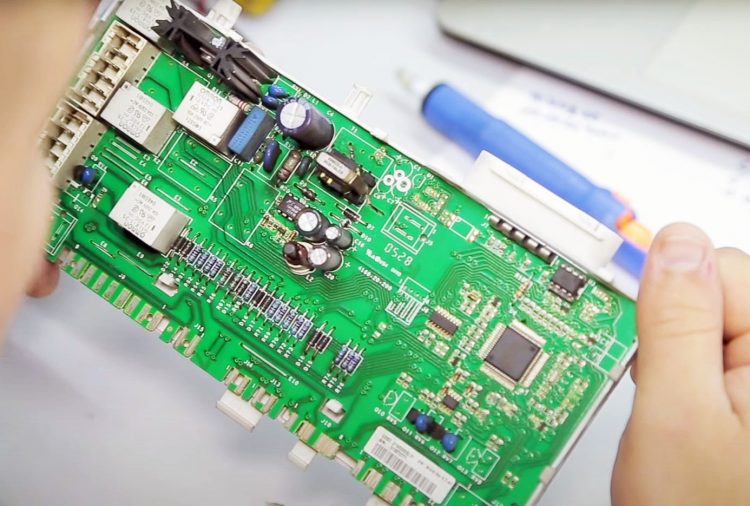

Failure of the control module

If a temporary malfunction occurs in the control module, it will be enough to disconnect the device for a while from the mains. The settings will be reset automatically, and the error will be fixed. After turning on the machine in the network, it will work as before.

In case of more severe problems with the control module, for example, when some elements burn out, they will need to be cleaned and sealed. If this does not help, the part will probably have to be replaced entirely with a new one. The repair of this level is best entrusted to the master.

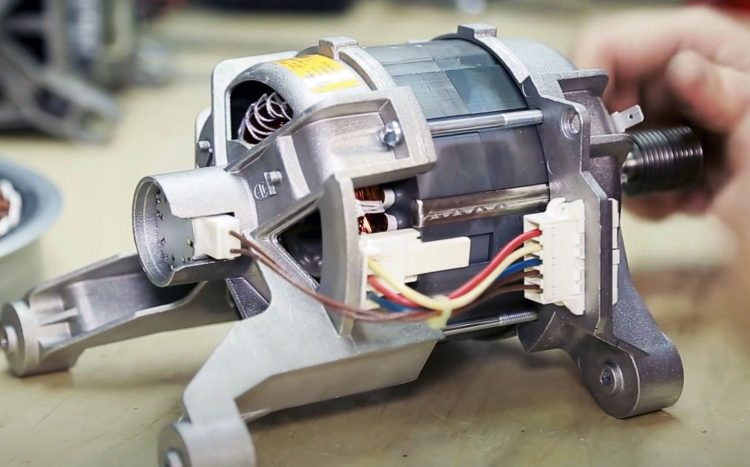

Failure of the whole engine or some element

In case of minor problems with the tachometer or vibration sensor, violation of contact with these parts, they should be diagnosed and cleaned.

When cleaning does not help, or severe damage to the engine or its parts is visually determined, a complete replacement cannot be dispensed with.

Removing and replacing the Hall sensor is done through the back of the device. To do this, you will need to remove the back panel of the machine, remove the drive belt, and carefully remove the wires so as not to damage them. Then remove the engine and replace the burned-out sensor.

Engine brushes and drive belt

Due to the extended drive belt, contact between the parts deteriorates, it slips during engine rotation, and the tachometer recognizes this as an error. The engine speed does not match the number of rotations of the drum. If the cause of error 3E is this – the belt must be replaced with a new one.

Erased engine brushes are also subject to replacement. So-called graphite rods mounted on the sides of the motor. They rub against its moving part and can be erased. And even if only one brush is out of order, both should be replaced at once.

Some of these situations can be visually recognized, and the problem can be fixed easily. But in case of problems with the internal parts of the machine, you will need to call the wizard and perform the repair of the device.