The F11 error code in the Whirlpool washer reports about the engine control board malfunction. Having found out this, a user will immediately adhere to household appliance repair specialists. But before doing it, try to apply the below-mentioned tricks which might eliminate the F11 error code.

Communication errors between components in the Whirlpool washer occur quite rarely. But this appliance is all about water, moisture, and spin at high speed. At a high humidity level, contacts tend to oxidize over time. Due to this, the bond between compounds is deteriorating.

Spin at high speeds creates vibration, which also affects wiring connections. Besides, users don’t always load the laundry correctly, which increases vibration during washing. Oxidation and vibration can significantly affect the bonding between elements of the Whirlpool washer. As a result, the F11 error code appears on the screen.

Therefore, you are to check the following points:

- Check the integrity of the harness connection with the motor control panel, motor, and central control panel.

- Analyze moving parts for worn out or broken components.

- Check the motor control panel.

4. Examine the main control panel of the Whirlpool washing machine.

5. Test the engine.

All the reasons mentioned above work forward the F11 error code appearance in the Whirlpool washer.

An engine

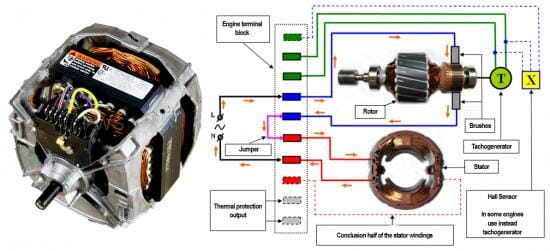

Check whether the connections of all engine joints. Also, examine its integrity. Commutator engine is the most spread ones. It is necessary to determine the designation of the contacts. There may be:

- Brush wires;

- Wires from the excitation winding;

- Wiring from the tachometer (speed sensor).

If you have experience in electrical engineering, you will handle the following engine checking tasks. Do it if you know what is a multimeter and how to use it. You should know how to read a circuit and understand the principles and basic rules of electricity.

There are two wires attached to the speed detector. It is located on the opposite end of the engine pulley. To identify them on the block, follow where the wires lead to. To test the sensor, you need to connect the terminals to the multimeter probes and check the loop. Some symbols will appear on the screen. If the values are changing when the engine rotates, it means that the sensor is in order.

A malfunction of this sensor might lead to unstable faults and failures of some modes, such as spin, etc.

Then see whether all the brushes are installed right and check the collector condition. The point is that deposit, cracks and other “surprises” might appear on it. If brushes are worn out, replace them. In case of deposit accumulation covering an anchor, clean it with rubber. If there are other problems with the anchor-like protruding burrs or visible failures of the integrity of lamellas or windings, it’s better to purchase a new part.

Using an ohmmeter, find the attached contacts couples.

There are an excitation winding and the anchor on the engine. We are going to check these elements for integrity. It makes no sense to measure winding resistance if you don’t know nominal values. To test its performance, you need to make a scheme.

Connect the excitation winding with the anchor consequentially. You have already determined which terminals contact each other, so there is winding between them. Interconnect them one by one from pairs (you need a crimp wire terminals), and apply 220V between the two remaining (one from brushes, another one from excitation).

Here is a typical scheme of switching on the washer engine. All items are signed.

If the engine is in order, the last option to check is the control board.

Control board

If the error occurs once, it can report about the control electronics failure. You can try to turn off the equipment for fifteen minutes from the network. Then, turn on the Whirlpool device again. If the error doesn’t disappear, you have to disassemble the washing machine and inspect the control board. Any visual defects, black traces, burnt-out elements are a clear sign that the engine control board is the reason for the F11 error message code.

You should check the quality of wires connection leading to the control board from the engine, including all connections in it. It happens that some contacts slightly move away. To solve the problem, return them to the previous position. Besides, specialists state that cleaning contacts will be useful, too.

The last thing you have to do is to go through the entire wiring system.

Although the wire breakage and burnout occur rarely, do not skip this stage of checking the appliance.

With careful testing of the Whirlpool washer, you will probably find the reason for the F11 error code. But if the visual inspection doesn’t produce results, then perhaps you will have to purchase a new engine control board.

The table of reasons and solutions for the f11 error code elimination in the Whirlpool washer

| Typical error f11 signs | The possible reason for the error appearance | Required measures |

| An automatic Whirlpool washer doesn’t start operating; the drum doesn’t spin; the appliance shows the F11 error code. | In most cases, the reason for malfunction relates to the Hall sensor (co-called tachogenerator or tachometer). This element controls rotation speed. 90% of all the issues occur precisely for the stated reason. | As a rule, the Hall sensor is beyond repair. So, the only solution is to replace it. On rare occasions, the resistor, placed with a sensor in one circuit, burns out. In this case, the resistor is the only element that needs changing. |

| The screen shows the F11 error code and the device doesn’t spin the drum. | An electronic controller, or simply a control module, has become unusable. This chip is paramount for an automatic washer as it is responsible for the entire unit. | As a rule, this control unit can be repaired. You will have to replace the damaged or burnt-out elements and solder the failed tracks. In particular cases, you need to replace the controller. But only a specialist should deal with this work. |

| An appliance continues to demonstrate the F11 error code, which doesn’t disappear after the control adjusting. | The washing machine engine is out of order. | The broken engine requires replacement. |

| From time to time, the technique shows the F11 error; the drum stops spinning. | Probably, the wiring connecting the engine with the control unit is worn out. During washing, the machine slightly vibrates, which can cause contact waste. The following signs are a shutdown and error appearance. | It is necessary to replace the loop of wires completely or to adjust the connection of the worn-out wires. |